131-meter wind blade

China’s Sany Renewable rolls out 131-meter wind blade

Manufacturer Sany Renewable Energy (Beijing) announces the launch of a 131-meter-long wind blade,

Implemented core blade design innovations that enable a more robust structure.

It maintained an optimized winged design with greater thickness and blunt rear end, and new manufacturing process technology helped the successful development.

Self-designed glass fiber pre-quilting technology, long-distance automatic infusion technology for large composite blades, and 3D design for trailing edge blind bonding inserts

Increased the durability and reliability of the blade.

-

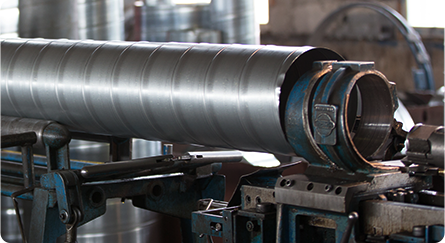

Glass fiber pre-quilting technology

Glass fiber pre-quilting technology is one of the important innovations in the manufacturing process of composite materials,

In particular, it plays a key role in the fabrication of large and complex structures such as large wind blades.

-

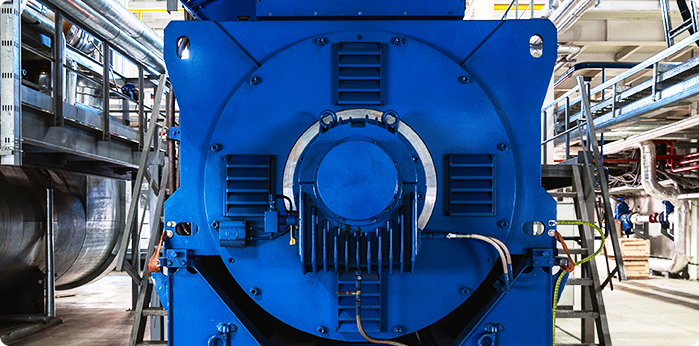

Long-range automatic injection technology

Long-range automatic injection technology is an innovative method used in the manufacturing of composite materials,

It plays an important role, especially in the production of large structures.

-

Follow-end bonding insert

Trailing edge blind bonding inserts are composite material structures,

In particular, it is an innovative technology used in the manufacturing process of wind turbine blades.

Technical progress, 131-meter wind blade

Increased blade durability and reliability in wind power generation

These technological advances are expected to play an important role in increasing the durability and reliability of blades in wind power generation.

Innovation will further strengthen competitiveness in the wind energy industry and contribute to improving the efficiency and performance of wind turbines.